Filling and capping machine – IC Filling Systems XP9ISO9HDC (2013)

Function:

Fully automatic rotary machine for rinsing, filling and capping bottles. The machine is designed for continuous operation in industrial beverage production and is equipped with a conveyor system, control panel and integrated units for all steps in the process.

Specifications:

-

Manufacturer: IC Filling Systems

-

Model: XP9ISO9HDC

-

Serial number: 13164

-

Model year: 2013

-

Electrical connection: 400 V, 50 Hz, 3-phase + 24 V

Measure:

– Length: approx. 3050 mm

– Width: approx. 1200 mm

– Height: approx. 1620 mm

Components and systems:

-

Rinsing module: Automatic rotating unit for internal rinsing of bottles

-

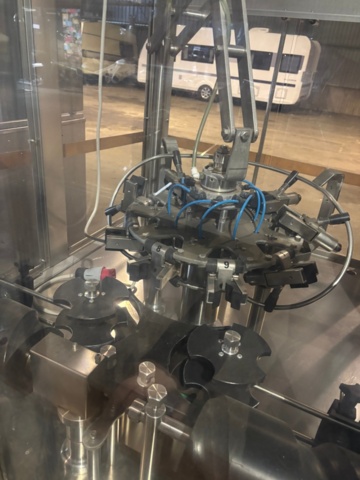

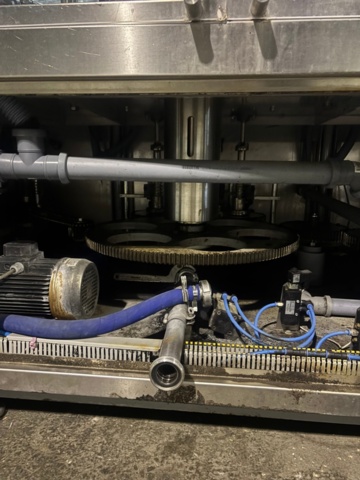

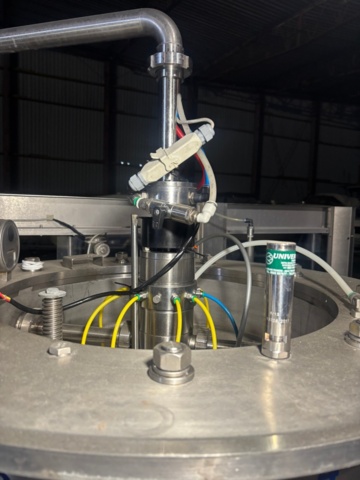

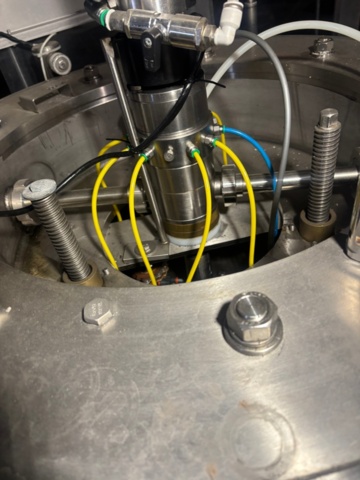

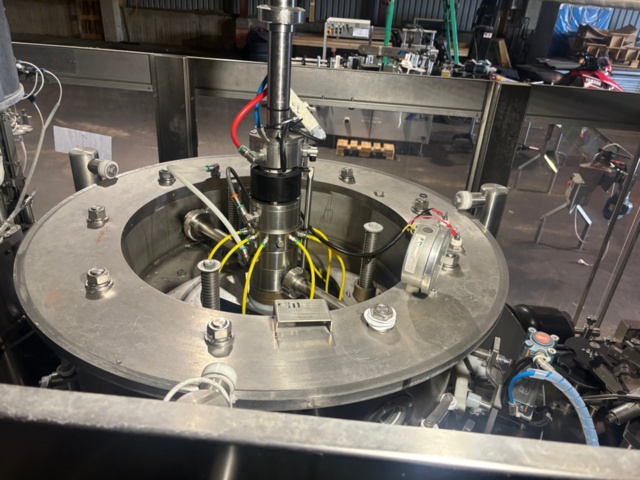

Filling module: 9-station rotary filling system with pneumatic controls

-

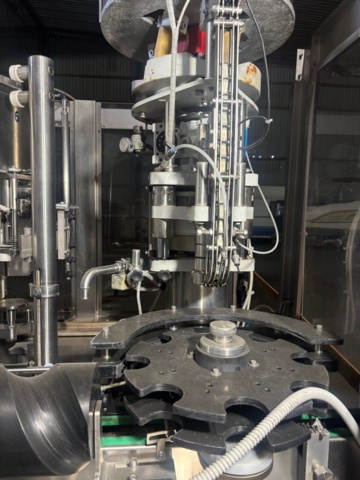

Encapsulation module:

-

Automatic cap applicator

-

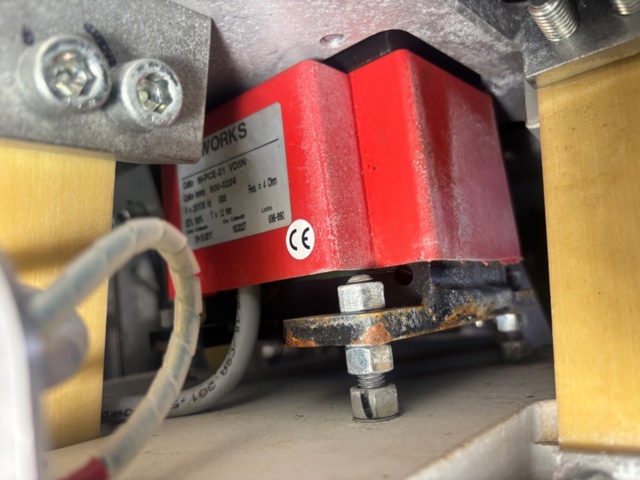

Cap magazine with motor and vibration feeder (Magnetic Works ML-PCE-21 VDSN)

-

-

Bottle flow:

-

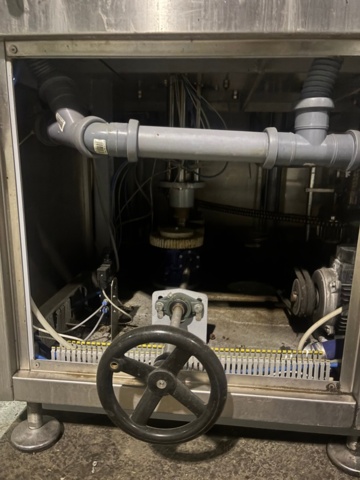

Bottle feeder with worm screw and star wheel

-

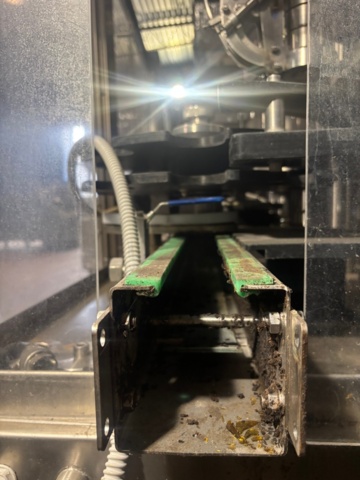

Integrated conveyor belt in the bottom of the machine

-

Control system and functions:

-

Control panel (Eaton) with separate controls for:

-

Vacuum pump

-

Filling pumps

-

Capsule feeding

-

Height adjustment

-

External cleaning

-

Start/stop

-

Automatic/manual modes

-

-

CE marked

-

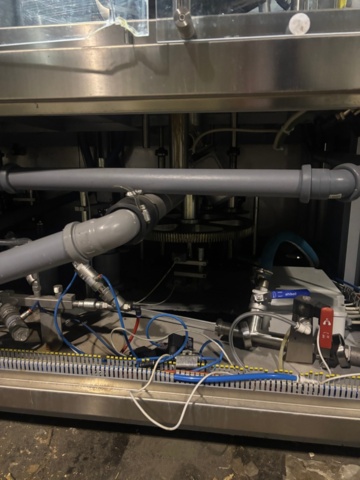

Pneumatics and sensors from, among others, Univer

-

Capping station equipped with safety guards and adjustment mechanisms

-

Internal piping and quick couplings for product flow and CIP

Other information:

-

Transparent plexiglass protective covers

-

Mounted on adjustable feet

-

Marked with manufacturing plate and serial number

-

The machine has clear marking of each station

-

Power connection via 5-pin CEE plug

-

Mechanical crank for manual height adjustment